Industrial IoT (IIoT)

1. what is Industrial IoT (IIoT)?

.jpeg)

Industrial IoT (IIoT) refers to the application of Internet of Things (IoT) technology in industrial environments, such as manufacturing, energy, transportation, and healthcare. It involves connecting machines, sensors, and devices to a centralized system, allowing real-time data collection, monitoring, and analysis. This technology helps businesses improve efficiency, reduce operational costs, and enhance decision-making through advanced analytics and automation. For example, in a factory, IIoT systems can track machine performance, detect faults, and predict maintenance needs before breakdowns occur, minimizing downtime and increasing productivity.

A key advantage of IIoT is predictive maintenance, which uses data from connected devices to identify potential equipment failures. This approach reduces unexpected breakdowns, extends the lifespan of machinery, and lowers repair costs. Additionally, IIoT enables remote monitoring, allowing managers to oversee operations from anywhere, improving safety and operational control. For instance, in the energy sector, IIoT can monitor oil rigs and pipelines to prevent leaks and other hazards. This real-time data collection helps companies respond quickly to emergencies, ensuring safer and more efficient operations.

AAs IIoT evolves, it is integrating with emerging technologies like artificial intelligence (AI) and edge computing to deliver even greater benefits. AI enhances data analysis, allowing systems to learn from patterns and make smarter decisions. Edge computing processes data closer to the source, reducing latency and improving response times. In the future, IIoT will drive innovations such as smart factories, autonomous supply chains, and improved sustainability efforts. However, it also brings challenges like cybersecurity risks and the need for robust data protection to secure sensitive industrial systems.

2.Predictive Maintenance

Predictive Maintenanceis a proactive maintenance strategy that uses data from sensors, machines, and advanced analytics to predict equipment failures before they occur. This approach helps organizations minimize downtime, reduce repair costs, and extend the lifespan of their assets. By continuously monitoring equipment conditions—such as temperature, vibration, and pressure—predictive maintenance identifies patterns and anomalies that signal potential issues. For example, in a manufacturing plant, sensors can detect unusual vibrations in a motor, allowing maintenance teams to fix the problem before it causes a breakdown.

One of the key benefits of predictive maintenance is its ability to optimize maintenance schedules based on actual equipment conditions rather than fixed timelines. This reduces unnecessary maintenance and prevents sudden failures, improving operational efficiency. Industries like aviation, energy, and healthcare rely heavily on predictive maintenance to ensure critical systems function smoothly. For instance, in the aviation industry, predictive maintenance helps monitor aircraft engines, reducing the risk of in-flight failures and improving passenger safety. By addressing problems early, companies save on emergency repairs and avoid production delays.

Advanced technologies like machine learning (ML) and Internet of Things (IoT) play a crucial role in enhancing predictive maintenance. ML algorithms analyze vast amounts of historical and real-time data to identify failure patterns, improving accuracy over time. IoT devices provide continuous monitoring and real-time updates, enabling quicker responses. As predictive maintenance evolves, it will become an essential tool for smart factories and industrial automation, driving cost savings and increasing operational reliability. However, successful implementation requires investment in data infrastructure, skilled personnel, and robust cybersecurity to protect sensitive operational data.

3. Industrial Automation

Industrial Automation

refers to the use of advanced technologies, such as robotics, control systems, and artificial intelligence (AI), to automate industrial processes and reduce human intervention. It enhances productivity, efficiency, and accuracy in manufacturing, assembly lines, and other industrial environments. Automation systems can handle repetitive tasks like packaging, welding, and quality control, allowing businesses to increase output while maintaining consistent product quality. For example, in the automotive industry, robotic arms perform tasks like assembling vehicle parts with precision and speed, reducing errors and production time.

A key component of industrial automation is the integration of Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems. PLCs manage real-time processes by controlling machinery based on programmed instructions, while SCADA systems monitor and collect data from multiple devices across a plant. This combination allows manufacturers to track operations remotely, identify inefficiencies, and respond quickly to equipment malfunctions. For instance, in the food industry, automation ensures consistent product packaging and quality inspection, minimizing human error and maintaining hygiene standards.

The future of industrial automation is driven by emerging technologies like the Industrial Internet of Things (IIoT), machine learning, and cyber-physical systems. These innovations enable smart factories where machines communicate with each other, optimize workflows, and predict maintenance needs. Automation not only reduces labor costs but also enhances worker safety by handling hazardous tasks. However, adopting automation requires significant investment in technology and workforce training. As industries move toward Industry 4.0, automation will play a crucial role in increasing operational efficiency, improving product quality, and enabling flexible manufacturing processes.

4.Digital Twins

Digital Twins are virtual models or digital replicas of physical objects, systems, or processes that allow real-time monitoring, simulation, and analysis. These digital representations are created using data collected from sensors and connected devices. By mirroring the physical world, digital twins help businesses analyze performance, predict issues, and optimize operations. For example, in manufacturing, a digital twin of a production line can simulate different scenarios to improve efficiency, reduce downtime, and enhance product quality without disrupting real-world processes.

One of the primary advantages of digital twins is their ability to provide predictive maintenance. By continuously collecting and analyzing data from physical assets, digital twins can identify patterns and predict equipment failures before they occur. This proactive approach reduces maintenance costs, extends the lifespan of machinery, and minimizes unexpected breakdowns. In sectors like aviation, digital twins of airplane engines track performance during flights and alert engineers to potential faults, improving passenger safety and operational reliability.

The future of digital twins is expanding with advancements in Artificial Intelligence (AI), Internet of Things (IoT), and cloud computing. These technologies enable more detailed and intelligent virtual models across industries such as healthcare, smart cities, and automotive. For instance, in healthcare, digital twins of human organs can assist in personalized treatment planning and surgical simulations. As the technology evolves, digital twins will play a critical role in optimizing complex systems, enhancing decision-making, and accelerating innovation across various domains.

5.Smart Manufacturing

Smart Manufacturing

refers to the use of advanced technologies like the Internet of Things (IoT), Artificial Intelligence (AI), Big Data, and automation to improve the efficiency, productivity, and flexibility of manufacturing processes. It connects machines, systems, and human workers to create intelligent production environments where real-time data is collected, analyzed, and used to optimize operations. For example, smart manufacturing enables automated quality checks during production, reducing human error and ensuring consistent product quality. This technology-driven approach enhances operational efficiency and lowers costs by minimizing waste and downtime.

One of the key features of smart manufacturing is predictive maintenance, where sensors monitor equipment conditions and provide early warnings of potential failures. This reduces unexpected breakdowns, extends machinery life, and improves overall productivity. For instance, in the automotive industry, smart manufacturing systems can track machine performance and automatically schedule maintenance, ensuring continuous production. Additionally, digital twins—virtual models of physical assets—allow manufacturers to simulate and optimize production processes without disrupting actual operations, leading to faster innovation and better resource management.

One of the key features of smart manufacturing is predictive maintenance, where sensors monitor equipment conditions and provide early warnings of potential failures. This reduces unexpected breakdowns, extends machinery life, and improves overall productivity. For instance, in the automotive industry, smart manufacturing systems can track machine performance and automatically schedule maintenance, ensuring continuous production. Additionally, digital twins—virtual models of physical assets—allow manufacturers to simulate and optimize production processes without disrupting actual operations, leading to faster innovation and better resource management.

6.IoT & Robotics

IoT & Robotics

is the integration of connected devices and intelligent robotic systems to automate tasks, enhance efficiency, and enable real-time monitoring. IoT connects physical devices through the internet, allowing them to communicate and share data. When combined with robotics, IoT enhances a robot’s ability to collect, process, and respond to information from its environment. For example, in smart warehouses, IoT-enabled robots track inventory, manage stock movement, and automate delivery processes. These systems work together to reduce human intervention, increase accuracy, and optimize operations across industries.

One of the significant benefits of IoT and robotics is remote monitoring and control. Robots equipped with IoT sensors can transmit data to centralized platforms, enabling operators to monitor and control robotic actions from anywhere. This is especially useful in hazardous environments like chemical plants or nuclear facilities, where human presence may be dangerous. In healthcare, IoT-powered surgical robots provide real-time data during procedures, improving precision and patient outcomes. Additionally, autonomous vehicles rely on IoT and robotics to navigate roads, detect obstacles, and communicate with traffic management systems for safe and efficient operation.

As technology advances, the future of IoT and robotics will involve greater machine-to-machine (M2M) communication and smarter decision-making capabilities. With the integration of Artificial Intelligence (AI), robots will learn from the data they collect, allowing them to adapt to new tasks and environments. In smart cities, IoT-enabled robots may manage public services like waste collection and security surveillance. This combination of IoT and robotics not only increases operational efficiency but also paves the way for autonomous, interconnected systems that enhance productivity and improve the quality of life.

7. SCADA Systems

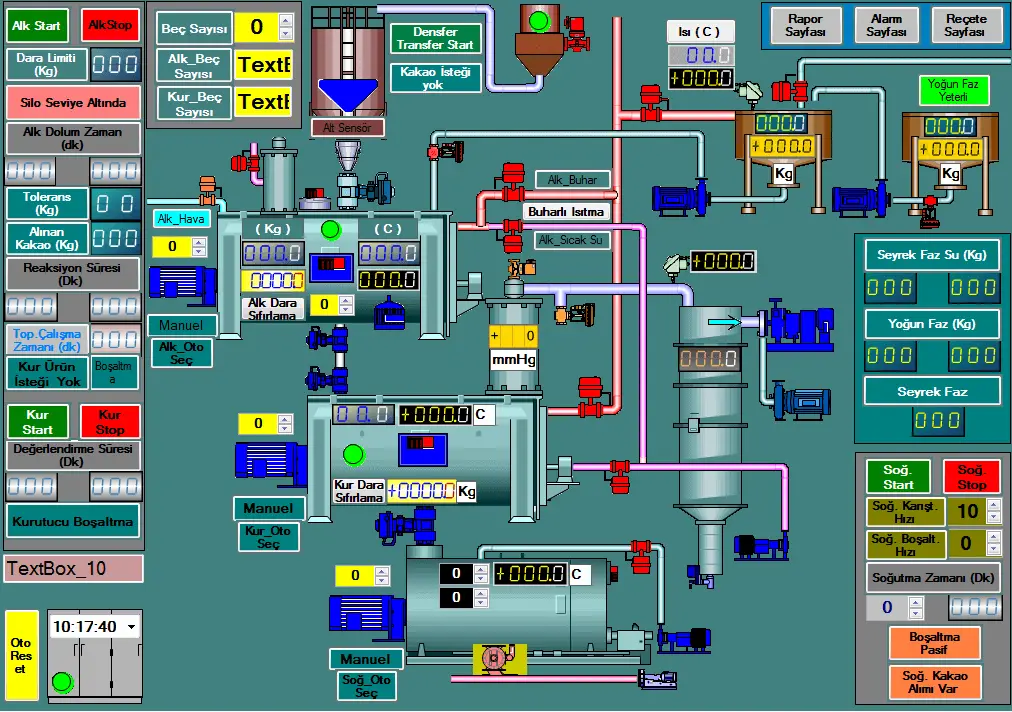

SCADA Systems are industrial control systems used to monitor, control, and manage critical infrastructure and processes in real-time. These systems collect data from sensors, devices, and machinery, allowing operators to supervise and control operations from a centralized location. SCADA systems are widely used in industries like power generation, water treatment, manufacturing, and oil and gas. For example, in a power plant, SCADA monitors equipment performance, detects faults, and allows engineers to make real-time adjustments to maintain efficiency and safety.

OA SCADA system consists of four key components: sensors and input devices, remote terminal units (RTUs), communication networks, and human-machine interfaces (HMIs). Sensors collect data such as temperature, pressure, and flow rates. RTUs gather this information and send it to the central control system via secure communication networks. Operators interact with the system through HMIs, which display real-time data and alerts. This setup enables remote monitoring and automated control, reducing the need for manual intervention and improving the speed and accuracy of decision-making.

One of the main concerns with SCADA systems is cybersecurity. As these systems become more connected to external networks, they are vulnerable to cyberattacks that can disrupt operations or compromise sensitive data. To enhance security, organizations implement firewalls, encryption, and regular system updates. Modern SCADA systems also integrate with IoT (Internet of Things) and cloud computing to provide advanced data analytics and predictive maintenance. This evolution allows industries to improve efficiency, reduce downtime, and respond quickly to potential issues, making SCADA systems essential for modern industrial automation.

8. Industrial Data Analytics

Industrial Data Analytics is the process of collecting, analyzing, and interpreting large volumes of data generated by industrial systems to improve operational efficiency, productivity, and decision-making. This data comes from sensors, machines, and other devices used in industrial settings such as manufacturing plants, power grids, and oil refineries. By applying advanced analytical techniques like machine learning, predictive modeling, and real-time monitoring, organizations can identify patterns, detect anomalies, and optimize processes. For example, in a manufacturing plant, industrial data analytics can monitor equipment performance and predict potential failures before they occur, reducing downtime and maintenance costs.

A key benefit of industrial data analytics is predictive maintenance. Traditional maintenance methods rely on fixed schedules, which can lead to unnecessary servicing or unexpected breakdowns. With data analytics, companies can track real-time equipment performance and predict when a machine is likely to fail. This approach not only extends the lifespan of machinery but also reduces repair costs and improves safety. Additionally, data analytics helps in quality control by analyzing production data to detect defects and ensure that products meet industry standards. This improves customer satisfaction and reduces waste in the production process.

Industrial data analytics also supports operational optimization and energy management. For instance, by analyzing energy consumption patterns, industries can identify areas of inefficiency and implement strategies to reduce energy costs. Moreover, real-time analytics enable faster decision-making by providing managers with accurate, up-to-date information. As industries embrace Industry 4.0 and the Industrial Internet of Things (IIoT), the role of data analytics is becoming more critical. It allows businesses to gain a competitive edge by improving efficiency, minimizing risks, and adapting quickly to changing market demands.

Comments